Fitting the Transmission Tunnel

Once the floor boards were set into position we began to fit the transmission tunnel supplied by Howell's Sheetmetal Co. The closest tunnel we could find was for a 1933 / 34 so a few modifications were need to fit our '32. We first added four inches to the length, ground down our welds and trimmed the excess metal from each side to better fit our project. We then used a hand nibbler to cut the holes for the hand brake and the shifter. The transmission is now ready for our POR-15 Rust Preventive Coating to be applied.

Checking the fit of the Transmission Tunnel supplied by Howell's Sheetmetal Co.

After test fitting the Transmission Tunnel we found it need to be lengthened so we cut it and added four inches to the length.

Welding complete and our tunnel has been lengthened four inches.

After welding the extension in place we cleaned the welds up with a grinder

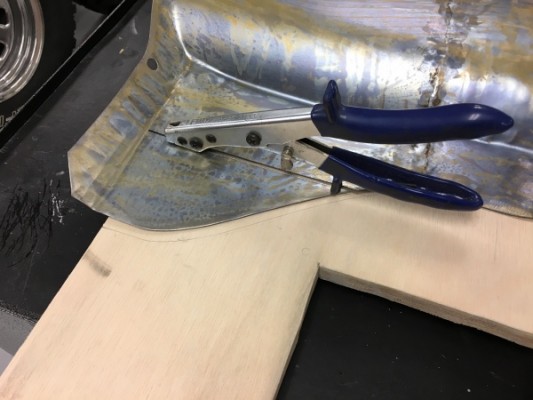

We used a hand nibbler to trim the excess metal from each side of the tunnel.

The hand brake hole cut and emergency brake handle have been installed and now we need to measure where to cut for the shifter.

We measured and are now using a hand nibbler to cut the hole in the transmission tunnel for the shifter.

The Transmission Tunnel is now fit and ready for the POR-15 Rust Preventive Coating 3-Step System to be applied.